Toolroom Bed Mill with Manual Quill Head

The Fryer MB-Q Series from Knox Manufacturing Solutions is the ultimate mill for toolroom applications. Designed and built to be the finest toolroom mill available, these machines are easier to use, more accurate and last longer than any other toolroom mill. Equipped with a manual quill and manual handwheels, the “Q” Series gives you the flexibility to use in manual, semi-CNC or full-CNC modes. The conversational control makes programming easy so even one-off parts can be done quickly and efficiently.

EASE OF USE

FEATURES

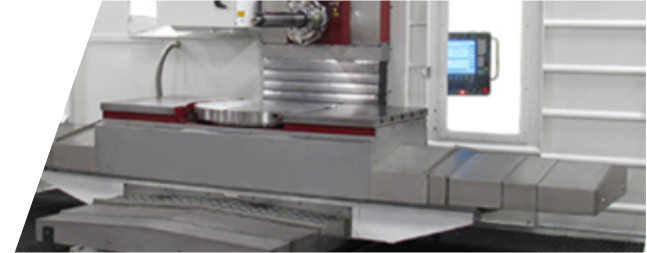

Toolroom Bed Mill with Rigid Spindle Head

The Fryer MB-R Series is the perfect mill for job shop and toolroom applications. Built to be the most accurate and reliable machine of its type, it is also extremely easy to use. Equipped with a rigid spindle and optional tool changer, this machine is capable of single or multi part production. The conversational control makes programming easy so even one-off parts can be done quickly and efficiently.

EASE OF USE

FEATURES

Precision Compact Mill

The Fryer CM Series is the perfect tool for toolroom, job shop and secondary operations. Built on a solid cast iron platform and using high precision ballscrews, spindle and ATC, the CM can hold the demanding tolerances that industry requires. Programming is accomplished with industry standard G code or Siemens advanced ‘Shop Mill’ programming. Equipped with an impressive list of standard features the CM Series is by far the best compact milling machine available today.

FEATURES

QUALITY