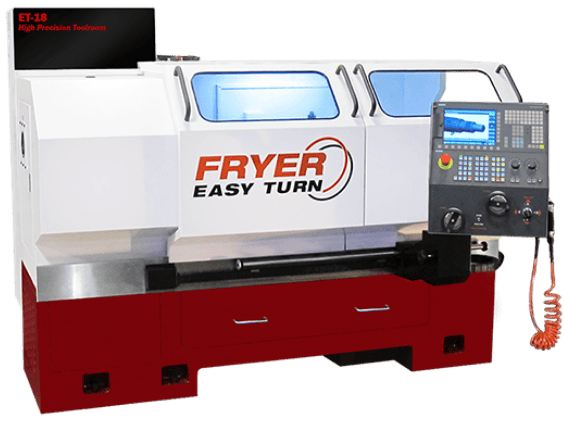

Easy Turn – Toolroom Turning

Designed by toolmakers for toolmakers, the Fryer Easy Turn Series from Knox Manufacturing Solutions provides rugged construction and high accuracy in a compact toolroom lathe. The Easy Turn is easier to use than a conventional lathe yet offers the productivity of a CNC. Time consuming manual set-ups for threading, chamfers, and contours are eliminated by the Easy Turn’s handle driven “Do One” cycles and electronic stops. Multi-mode operations allow manual use, semi-auto use and full CNC operation. This flexibility is perfect for repair shops, tool and die, prototype and job shops alike.

EASE OF USE

QUALITY

Easy Turn – Large Capacity Turning

Heavy duty construction distinguishes the ET Large Capacity Series lathes. Designed for applications where high rigidity is required, these machines can be custom configured for your most demanding applications. Easy-to-use operator interface allows simple shop floor programming for one-off parts. High performance drives and motors combine with standard G-Code interface allowing production to run smoothly and efficiently.

EASE OF USE

QUALITY

Easy Turn – Extra Large Capacity Turning

Fryer Machine’s ET-XL Series Lathes provide the ultimate in performance for your large part machining needs. These wide bed (30”) heavy duty engine lathes provide incredible capacity to handle the toughest jobs you have. Designed as the heaviest machines in its class, these machines feature centers distances up to 340” and spindle bores up to 20”. Innovative features like live tooling, C axis, Y axis, automatic chucks and auto steady rests allow you to customize the machine to best suit your application. The standard Fryer / Siemens 828-HS control features automated set-up and both easy conversational and industry-standard G Code programming. Also featured are thread repair, milling cycles, dual handwheels and incredible reliability.

FEATURES

QUALITY