For details on all Mazak HCN Series machines click here

The HCN world-class lineup of horizontal machining centers combines outstanding value with high-performance features, enabling manufacturers to achieve maximum productivity when working with virtually any type of material. Furthermore, while these machines require minimal floor space, they still provide exceptionally wide machining areas for handling large workpieces.

SERIES CHARACTERISTICS

- Pallet size range from 400 mm square to 1,250 mm square

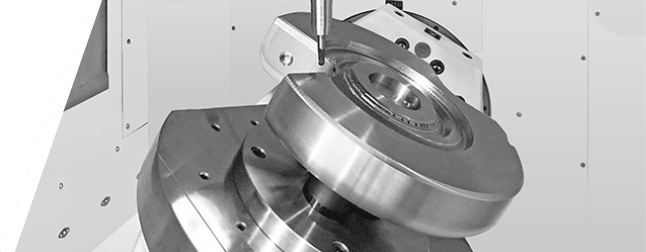

- Wide variety of spindle specifications featuring #40 and #50 taper spindle designs for high-speed, high-horsepower and high-torque metal cutting performance

- Ballscrew Core Cooling (XYZ) standard to ensures thermal stability over long machining cycles

- Highest maximum workpiece diameter, height and weight in its class

- Cam-driven automatic tool changer function ensuring high speed and reliable tool change cycles

- Machines pre-engineered for integration into factory automation including Mazak’s PALLETECH Manufacturing Cell

- Wide variety of tool magazines and tool hives to 330 tools to meet the wide variety of work piece lot size and unattended production

- Table work piece variations available providing high speed, high accuracy work piece positioning

- The industry’s fastest Two Pallet Changer as standard with rotating front pallet for ease of set up

- Ergonomic friendly machine designs featuring large windows, swiveling operation panel, ease of part & tool loading, and easy access into maintenance areas.

- Touch Probe Ready Spindle designs allowing ease of field installation