Whether your application calls for small or large part machining in a low- or high-volume production environment, we offer an extensive range of vertical machining centers to ensure you have the best solution for your needs with the lowest cost of ownership in the industry.

The Kentucky-built VC-Ez Series of vertical machining centers places Mazak quality and reliability within reach for virtually any shop, with productive, space-saving efficiency at an affordable price. Available options include auto tool changer capacities, chip/coolant management solutions and a wide range of spindle configurations.

Enhanced ergonomics and a generous work area make these machines easy to use, load and unload for operators and automation solutions alike. To simplify setup and speed up production, cutting-edge SMOOTH TECHNOLOGY software solutions on the MAZATROL SmoothEz CNC handle everything from advanced thermal management to offline programming.

SERIES CHARACTERISTICS

The VCN Series of vertical machining centers are built with more productivity-enhancing features than any other verticals in their class. The series combines advanced technology, productivity and value for a wide variety of machining applications. This makes them an incredible value for shops large and small. Equipped with advanced controls that provides conversational or EIA programming, machines in this series give the capability and productivity necessary for today’s technology driven shops.

SERIES CHARACTERISTICS

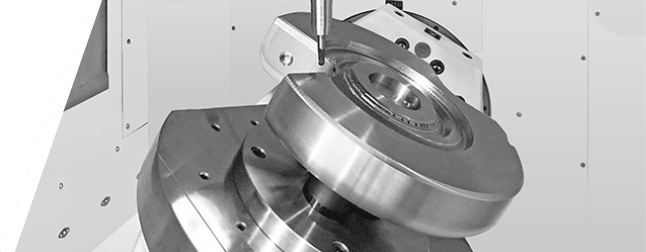

The VERTICAL TRAVELING COLUMN (VTC) Series of vertical machining centers features a full traveling column design and fixed tables for machining of extremely long and heavy workpieces. In addition, with an optional table center partition the machine work envelop can be divided into two separate work areas that allow the machine to be in cycle in one work area, while a part is being unloaded/loaded or a new set up in the other work area. VTC table lengths from 78” to 154” will handle a large variety of oversize workpieces. Spindles are available in many configurations, such as, standard, high-torque, high-speed with CAT-40 and CAT-50 tapers – Big Plus or standard taper, and the 5 axis VTC800 S/R features a swivel spindle (B axis).

All the machines are perfect for long aerospace parts, conveyor sections, and more. Machines can also be outfitted with rotary tables for increased part processing versatility.

SERIES CHARACTERISTICS